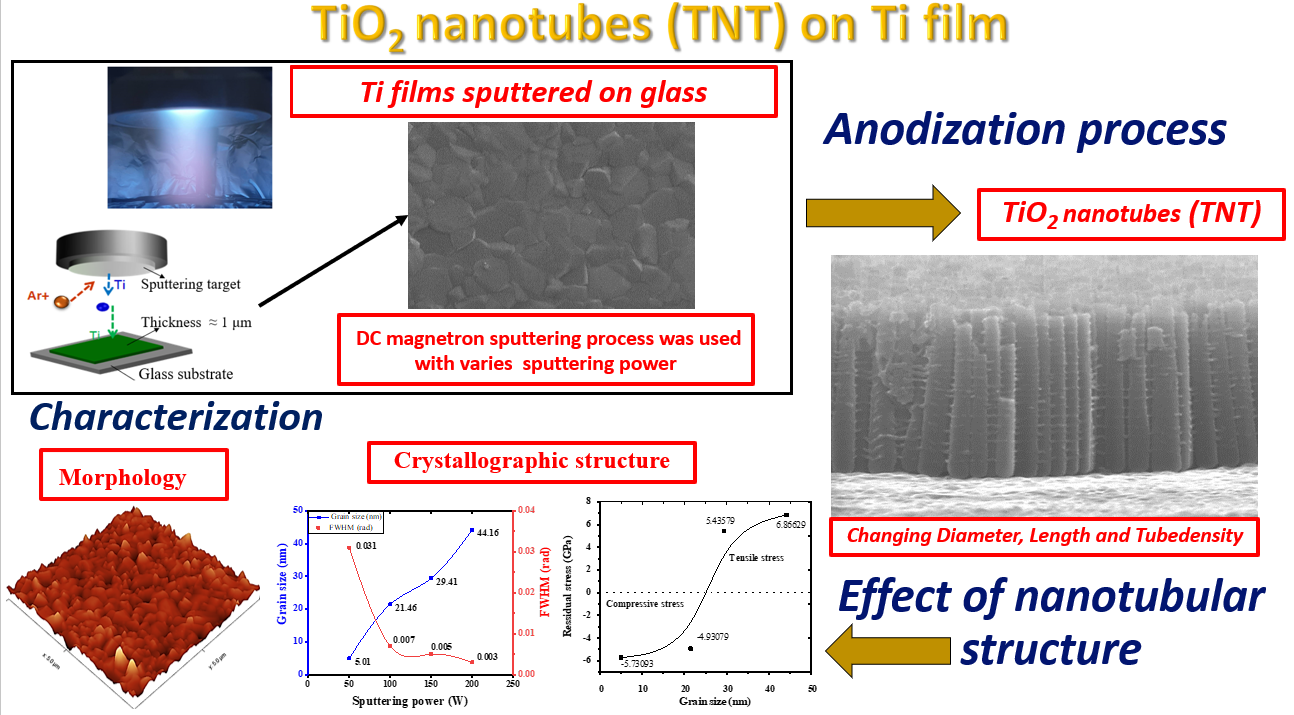

Effects of sputtering power of Ti films on morphology of TiO2 nanotubes synthesized via anodization process

DOI:

https://doi.org/10.55713/jmmm.v32i2.1256คำสำคัญ:

Ti films, sputtering power, anodization, TiO2 nanotubesบทคัดย่อ

In this paper, we aimed to find the sputtering power most suitable for fabricating anodized TiO2 nanotubes (TNTs) with high dimensions (diameter and length). TNTs were synthesized via anodization of Ti films deposited on a glass substrate at varying sputtering power from 50 W to 200 W. The properties of Ti films such as crystallinity, residual stress, and roughness were investigated, which affected the morphology of TNTs. Sputtering power levels of 150 W and 200 W were suitable for TNTs formation via the anodization process in NH4F concentrations from 1.0 wt% to 2.5 wt% due to the increased density and crystallinity of Ti films. Boosting the sputtering power to 200 W increases the roughness of the surface, resulting in a decrease in tube diameter and length. Increasing the sputtering power to 200 W also causes the residual stress of the film to be converted from compression to tensile stress, which allows for more TNTs structures to be formed on the film. Nanotubes fabricated on 150 W sputtered films have been proven to be superior to those fabricated at 200 W in every NH4F concentration in terms of length and diameter. Thus, they are more suitable for applications.

Downloads

เอกสารอ้างอิง

Y. Kwon et al., "Enhanced ethanol sensing properties of TiO2 nanotube sensors," Sensors and Actuators B: Chemical, vol. 173, pp. 441–446, 2012. DOI: https://doi.org/10.1016/j.snb.2012.07.062

P. Roy, S. P. Albu, and P. Schmuki, "TiO2 nanotubes in dye-sensitized solar cells: Higher efficiencies by well-defined tube tops," Electrochemistry Communications, vol. 12, no. 7, pp. 949–951, 2010. DOI: https://doi.org/10.1016/j.elecom.2010.04.029

Y. S. Sohn, Y. R. Smith, M. Misra, and V. (Ravi) Subramanian, "Electrochemically assisted photocatalytic degradation of methyl orange using anodized titanium dioxide nanotubes," Applied Catalysis B: Environmental, vol. 84, no. 3–4., pp. 372–378, 2008. DOI: https://doi.org/10.1016/j.apcatb.2008.04.021

S. Jafari, B. Mahyad, H. Hashemzadeh, S. Janfaza, T. Gholikhani, and L. Tayebi, "Biomedical Applications of TiO2 Nanostructures: Recent Advances," International Journal of Nanomedicine, vol. 15, pp. 3447–3470, 2020. DOI: https://doi.org/10.2147/IJN.S249441

E. M. Elsayed, N. F. Attia, and L. A. Alshehri, "Innovative Flame Retardant and Antibacterial Fabrics Coating Based on Inorganic Nanotubes," Chemistry Select, vol. 5, no. 10, pp. 2961–2965, 2020. DOI: https://doi.org/10.1002/slct.201904182

N. F. Attia and M. Mousa, "Synthesis of smart coating for furniture textile and their flammability and hydrophobic properties," Progress in Organic Coatings, vol. 110, pp. 204–209, 2017. DOI: https://doi.org/10.1016/j.porgcoat.2017.04.035

N. F. Attia, "Organic nanoparticles as promising flame retardant materials for thermoplastic polymers," Journal of Thermal Analysis and Calorimetry, vol. 127, no. 3, pp. 2273–2282, 2016. DOI: https://doi.org/10.1007/s10973-016-5740-z

H. K. Sung et al., "Enhanced Power Conversion Efficiency of Dye-Sensitized Solar Cells by Band Edge Shift of TiO2 Photoanode," Molecules, vol. 25, no. 7, p. 1502, Mar. 26, 2020. DOI: https://doi.org/10.3390/molecules25071502

X. Yu et al., "One-step ammonia hydrothermal synthesis of single crystal anatase TiO2 nanowires for highly efficient dye-sensitized solar cells," Journal of Materials Chemistry A, vol. 1, no. 6, pp. 2110–2117, 2013. DOI: https://doi.org/10.1039/C2TA00494A

J. Wang, S. Qu, Z. Zhong, S. Wang, K. Liu, and A. Hu, "Fabrication of TiO2 nanoparticles/nanorod composite arrays via a two-step method for efficient dye-sensitized solar cells," Progress in Natural Science: Materials International, vol. 24, no. 6, pp. 588–592, 2014. DOI: https://doi.org/10.1016/j.pnsc.2014.10.013

F. Mohammadpour and M. Moradi, "Double-layer TiO2 nanotube arrays by two-step anodization: Used in back and front-side illuminated dye-sensitized solar cells," Materials Science in Semiconductor Processing, vol. 39, pp. 255–264, 2015. DOI: https://doi.org/10.1016/j.mssp.2015.04.048

A. Abd Aziz, "Synthesis and Characterization of TiO2 Nanotube Using Electrochemical Anodization Method," International Journal of Engineering Technology and Sciences, vol. 5, no. 3, pp. 132–139, 2018. DOI: https://doi.org/10.15282/ijets.v5i3.1136

B. Li, X. Gao, H.-C. Zhang, and C. Yuan, "Energy Modeling of Electrochemical Anodization Process of Titanium Dioxide Nanotubes, " ACS Sustainable Chemistry & Engineering, vol. 2, no. 3. American Chemical Society (ACS), pp. 404–410, 2013. DOI: https://doi.org/10.1021/sc400304h

J. M. Macak, H. Tsuchiya, S. Berger, S. Bauer, S. Fujimoto, and P. Schmuki, "On wafer TiO2 nanotube-layer formation by anodization of Ti-films on Si," Chemical Physics Letters, vol. 428, no. 4–6, pp. 421–425, 2006. DOI: https://doi.org/10.1016/j.cplett.2006.07.062

Y. Tang, J. Tao, Z. Dong, J. T. Oh, and Z. Chen, "The formation of micrometer-long TiO2 nanotube arrays by anodization of titanium film on conducting glass substrate," Advances in Natural Sciences: Nanoscience and Nanotechnology, vol. 2, no. 4, p. 045002, 2011.

K. N. Chappanda, Y. R. Smith, L. W. Rieth, P. Tathireddy, M. Misra, and S. K. Mohanty, "Effect of sputtering parameters on the morphology of TiO2 nanotubes synthesized from thin Ti film on Si substrate," IEEE Transactions on Nanotechnology, vol. 14, no. 1, pp. 18–25, 2015. DOI: https://doi.org/10.1109/TNANO.2014.2360501

H. I. Jaafar, A. M. A. Alsammerraei, and H. H. Hamdan, "Study of the effect of NH4F concentration on the sutrcture of electrochemically prepared TiO2 nanotubes," Iraqi Journal of Science, vol. 53, no. 2, p. 827-831, 2012.

J. V. Pasikhani, N. Gilani, and A. E. Pirbazari, "The effect of the anodization voltage on the geometrical characteristics and photocatalytic activity of nanotube arrays," Nano-Structures & Nano-Objects, vol. 8, pp. 7–14, 2016.

A. M. A. Alsammarraei, H. I. Jaafar, K. N. Abed, "The role of anodizing potentials in making TiO2 nanotubes in (ethylene glycol / NH4F /water) electrolyte," Archives of Applied Science Research, vol. 6, no. 2, pp. 115-121, 2014.

M. W. Liao and C. K. Chung, "The role and effect of residual stress on pore generation during anodization of aluminium thin films," Corrosion Science, vol. 74, pp. 232–239, 2013.

G. K. Mor, O. K. Varghese, M. Paulose, N. Mukherjee, and C. A. Grimes, "Fabrication of tapered, conical-shaped titania nanotubes," Journal of Materials Research, vol. 18, no. 11, pp. 2588–2593, 2003. DOI: https://doi.org/10.1557/JMR.2003.0362

J. M. Macak et al., "TiO2 nanotubes: Self-organized electrochemical formation, properties and applications," Current Opinion in Solid State and Materials Science, vol. 11, no. 1–2, pp. 3–18, 2007. DOI: https://doi.org/10.1016/j.cossms.2007.08.004

K. Yasuda, J. M. Macak, S. Berger, A. Ghicov, and P. Schmuki, "Mechanistic Aspects of the Self-Organization Process for Oxide Nanotube Formation on Valve Metals," Journal of The Electrochemical Society, vol. 154, no. 9, p. C472, 2007. DOI: https://doi.org/10.1149/1.2749091

U. H. Shah, K. M. Deen, H. Asgar, Z. Rahman, and W. Haider, "Understanding the mechanism of TiO2 nanotubes formation at low potentials (≤ 8 V) through electrochemical methods," Journal of Electroanalytical Chemistry, vol. 807, pp. 228–234, 2017. DOI: https://doi.org/10.1016/j.jelechem.2017.11.014

F. M. D’Heurle and J. M. E. Harper, "Note on the origin of intrinsic stresses in films deposited via evaporation and sputtering," Thin Solid Films, vol. 171, no. 1, pp. 81–92, 1989. DOI: https://doi.org/10.1016/0040-6090(89)90035-7

A. J. Detor et al., "Stress and microstructure evolution in thick sputtered films, " Acta Materialia, vol. 57, no. 7, pp. 2055–2065, 2009. DOI: https://doi.org/10.1016/j.actamat.2008.12.042

Y. K. V. Reddy, D. Mergel, S. Reuter, V. Buck, and M. Sulkowski, "Structural and optical properties of BaTiO3 thin films prepared by radio-frequency magnetron sputtering at various substrate temperatures," Journal of Physics D: Applied Physics, vol. 39, no. 6, pp. 1161–1168, 2006. DOI: https://doi.org/10.1088/0022-3727/39/6/023

M. W. Liao and C. K. Chung, "The role and effect of residual stress on pore generation during anodization of aluminium thin films," Corrosion Science, vol. 74, pp. 232–239, 2013. DOI: https://doi.org/10.1016/j.corsci.2013.04.047

A. Y. Chen et al., "Deposition-rate dependence of orientation growth and crystallization of Ti thin films prepared by magnetron sputtering," Thin Solid Films, vol. 574, pp. 71–77, 2015. DOI: https://doi.org/10.1016/j.tsf.2014.10.053

Y. Q. Fu et al., "Advances in piezoelectric thin films for acoustic biosensors, acoustofluidics and lab-on-chip applications," Progress in Materials Science, vol. 89, pp. 31–91, 2017. DOI: https://doi.org/10.1016/j.pmatsci.2017.04.006

J. Jaiswal et al., "Enhanced Optical Absorption of Ti Thin Film: Coupled Effect of Deposition and Post-deposition Temperatures," JOM, vol. 69, no. 11, pp. 2383–2389, 2017. DOI: https://doi.org/10.1007/s11837-017-2546-9

M. Chinmulgund, R. B. Inturi, and J. A. Barnard, "Effect of Ar gas pressure on growth, structure, and mechanical properties of sputtered Ti, Al, TiAl, and Ti3Al films," Thin Solid Films, vol. 270, no. 1–2, pp. 260–263, 1995. DOI: https://doi.org/10.1016/0040-6090(95)06990-9

X. Pang, L. Zhang, H. Yang, K. Gao, and A. A. Volinsky, "Residual Stress and Surface Energy of Sputtered TiN Films," Journal of Materials Engineering and Performance, vol. 24, no. 3, pp. 1185–1191, 2015. DOI: https://doi.org/10.1007/s11665-015-1393-5

Y. Tang, J. Tao, Z. Dong, J. T. Oh, and Z. Chen, "The formation of micrometer-long TiO2 nanotube arrays by anodization of titanium film on conducting glass substrate," Advances in Natural Sciences: Nanoscience and Nanotechnology, vol. 2, no. 4, p. 045002, 2011. DOI: https://doi.org/10.1088/2043-6262/2/4/045002

C. Lin, S. Chen, and L. Cao, "Anodic formation of aligned and bamboo-type TiO2 nanotubes at constant low voltages," Materials Science in Semiconductor Processing, vol. 16, no. 1, pp. 154–159, 2013. DOI: https://doi.org/10.1016/j.mssp.2012.05.009

R. Kojima, Y. Kimura, M. Bitoh, M. Abe, and M. Niwano, "Investigation of Influence of Electrolyte Composition on Formation of Anodic Titanium Oxide Nanotube Films," Journal of The Electrochemical Society, vol. 159, no. 11. pp. D629–D636, 2012. DOI: https://doi.org/10.1149/2.003211jes

D. Regonini, A. Satka, A. Jaroenworaluck, D. W. E. Allsopp, C. R. Bowen, and R. Stevens, "Factors influencing surface morphology of anodized TiO¬2 nanotubes," Electrochimica Acta, vol. 74, pp. 244–253, 2012. DOI: https://doi.org/10.1016/j.electacta.2012.04.076

A. Stróż, G. Dercz, B. Chmiela, D. Stróż, and B. Łosiewicz, "Electrochemical Formation of Second Generation TiO2 Nanotubes on Ti13Nb13Zr Alloy for Biomedical Applications," Acta Physica Polonica A, vol. 130, no. 4, pp. 1079–1080, 2016. DOI: https://doi.org/10.12693/APhysPolA.130.1079

H. Amani Hamedani et al., "Synthesis and Growth Mechanism of Thin-Film TiO2 Nanotube Arrays on Focused-Ion-Beam Micropatterned 3D Isolated Regions of Titanium on Silicon," ACS Applied Materials & Interfaces, vol. 5, no. 18, pp. 9026–9033, 2013. DOI: https://doi.org/10.1021/am402203m

S. Farsinezhad, A. Mohammadpour, M. Benlamri, A. N. Dalrymple, and K. Shankar, "The Morphology of TiO2 Nanotube Arrays Grown from Atomically Peened and Non-Atomically Peened Ti Films," Journal of Nanoscience and Nanotechnology, vol. 17, no. 7, pp. 4936–4945, 2017. DOI: https://doi.org/10.1166/jnn.2017.13310

A. Apolinário et al., "The role of the Ti surface roughness in the self-ordering of TiO2 nanotubes: a detailed study of the growth mechanism," J. Mater. Chem. A, vol. 2, no. 24, pp. 9067–9078, 2014. DOI: https://doi.org/10.1039/C4TA00871E

ดาวน์โหลด

เผยแพร่แล้ว

วิธีการอ้างอิง

ฉบับ

บท

การอนุญาต

ลิขสิทธิ์ (c) 2022 Journal of Metals, Materials and Minerals

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.