Effect of trisilanol isobutyl polyhedral oligomeric silsesquioxane (TPOSS) in recycled PET (rPET) and polypropylene based compound: Investigation on mechanical properties

DOI:

https://doi.org/10.55713/jmmm.v33i3.1693คำสำคัญ:

Recycled polyethylene terephthalate, Polypropylene, Melt spinning, Compounding, Mechanical propertiesบทคัดย่อ

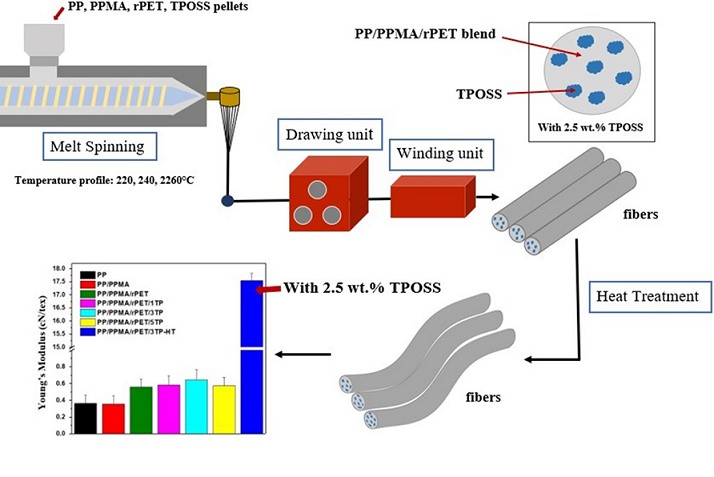

Recycled polyethylene terephthalate is successfully prepared. This project is involved for “Circular economy” policy. It is successfully prepared into powder form by nano-grinder technique. 10 phr of PP-g-MA and 1 phr to 5 phr of TPOSS are added for compatibilizer and mechanical properties enhancement, respectively. PP-g-MA can form the chemical linkage of the anhydride groups with the polyamide end groups. 20 wt% of recycled polyethylene terephthalate powder and polypropylene based compound is successfully fabricated by melt mixing. Then, it is fabricated by melting spinning technique. Fourier transform infrared presents Si-O-Si linkage in binary blend compound. X-ray diffraction pattern reports that single phase is obtained. Adding TPOSS can be induced to crystallinity enhancement. No significant change of thermal properties was observed from room temperature to 300℃. Scanning electron microscope reports that with the PP-g-MA provides smoothness of surface. Recycled polyethylene terephthalate is uniformly distributed. Melting and crystallization temperatures are reported to be 162℃ to 167℃ and 115℃ to 120℃, respectively. All of throughput rate is reported to be 1.8 g⸳min-1 to 2.3 g⸳min-1. With the existence of TPOSS, the mechanical properties of compound are slightly increased. TPOSS are added for mechanical properties enhancement. The polymer compound presents the excellent properties. It is remarkable to note that recycled polyethylene terephthalate is considered as an excellent candidate for use as raw material for polymer compound production.

Downloads

เอกสารอ้างอิง

J. Nyika, and M. Dinka, "Recycling plastic waste materials for building and construction Materials: A minireview," Materials Today: Proceedings, vol. 62, pp. 3257-3262, 2022.

G. Thomassen, S. Van Passel, L. Alaerts, and J. Dewulf, "Retrospective and prospective material flow analysis of the post-consumer plastic packaging waste management system in Flanders," Waste Management, vol. 147, pp. 10-21, 2022.

S. Schweizer, A. Becker-Staines, and T. Tröster, "Separation and reclamation of automotive hybrid structures made of metal and fibre-reinforced plastic," Waste Management, vol. 115, pp. 74-82, 2020.

J. Wang, J. Jiang, J. Ding, X. Wang, Y. Sun, R. Ruan, A. J. Ragauskas, Y. S. Ok, and D. C. W. Tsang, "Promoting diels-alder reactions to produce bio-BTX: Co-aromatization of textile waste and plastic waste over USY zeolite," Journal of Cleaner Production, vol. 314, p. 127966, 2021.

R. Geyer, J. R. Jambeck, and K. L. Law, "Production, use, and fate of all plastics ever made," Science Advances, vol. 3, no. 7, 2017.

Q. Wang, A. Tweedy, and H. G. Wang, "Reducing plastic waste through legislative interventions in the United States: Development, obstacles, potentials, and challenges," Sustainable Horizons, vol. 2, p. 100013, 2022.

K. P. Gopinath, V. M. Nagarajan, A. Krishnan, and R. Malolan, "A critical review on the influence of energy, environmental and economic factors on various processes used to handle and recycle plastic wastes: Development of a comprehensive index," Journal of Cleaner Production, vol. 274, p. 123031, 2020.

C. Wang, H. Han, Y. Wu, and D. Astruc, "Nanocatalyzed upcycling of the plastic wastes for a circular economy," Coordination Chemistry Reviews, vol. 458, p. 214422, 2022.

S. N, "Plastic waste management: A road map to achieve circular economy and recent innovations in pyrolysis," Science of The Total Environment, vol. 809, p. 151160, 2022.

P. Gupta, and S. Bhandari, "6-Chemical depolymerization of PET bottles via ammonolysis and aminolysis," in Recycling of Polyethylene Terephthalate Bottles, S. Thomas, A. Rane, K. Kanny, A. V. K, and M. G. Thomas, Eds.: William Andrew Publishing, 2019, pp. 109-134.

C.-Q. Li, J.-W. Zha, H.-Q. Long, S.-J. Wang, D.-L. Zhang, and Z.-M. Dang, "Mechanical and dielectric properties of graphene incorporated polypropylene nanocomposites using polypropylene-graft-maleic anhydride as a compatibilizer," Composites Science and Technology, vol. 153, pp. 111-118, 2017.

X. Zhou, Y. Cao, K. Yang, P. Yu, W. Chen, S. Wang, and M. Chen "Clean plasma modification for recycling waste plastic bags: From improving interfacial adhesion with wood towards fabricating formaldehyde-free plywood," Journal of Cleaner Production, vol. 269, p. 122196, 2020.

R.-C. Silvia, M-F. Angel, A-S. Alejandro, N-C. Rodrigo, R-H. Aurelio, B-G. José Eduardo, and D. E. Páramo Calderón, "Modification of banana starch (Musa paradisiaca L.) with polyethylene terephthalate: Virgin and bottle waste," Carbohydrate Research, vol. 508, p. 108401, 2021.

W. Zhang, G. Camino, and R. Yang, "Polymer/polyhedral oligomeric silsesquioxane (POSS) nanocomposites: An overview of fire retardance," Progress in Polymer Science, vol. 67, pp. 77-125, 2017.

S. Hu, X. Chen, M. A. Bin Rusayyis, N. S. Purwanto, and J. M. Torkelson, "Reprocessable polyhydroxyurethane networks reinforced with reactive polyhedral oligomeric silsesquioxanes (POSS) and exhibiting excellent elevated temperature creep resistance," Polymer, vol. 252, p. 124971, 2022.

W. Zhao, Y. Huang, R. Chen, H. Peng, Y. Liao, and Q. Wang, "Facile preparation of thioether/hydroxyl functionalized polyhedral oligomeric silsesquioxanes hybrid polymer for ultrahigh selective adsorption of silver(I) ions," Reactive and Functional Polymers, vol. 163, p. 104899, 021.

A. Zhang, J. Wang, G. Wang, L. Jiang, X. Meng, and G. Zhao, "Microcellular injection molded lightweight, strong and thermally insulating PP/fibrillated-PTFE composite foams with enhanced surface appearance," Journal of Materials Research and Technology, vol. 22, pp. 2933-2943, 2023.

I. Debbah, R. Krache, K. Belkouissem, D. Benachour, and M. E. Cagiao, "Effect of a thermoplastic elastomer compatibilizer (sebs-g-mah) on the properties of PP/PET blends," Roumanian Journal of Chemistry, vol. 63, pp. 11-20, 2018.

P. A. Ling, and H. Ismail, "Tensile properties, water uptake, and thermal properties of polypropylene/waste pulverized tire/kenaf (PP/WPT/KNF) composites," BioResources, vol. 8, no. 1, pp. 806-817, 2013.

M. J. Chinchillas-Chinchillas, V. Orozco-Carmona, C. G. Alvarado- Beltrán, J. Almaral-Sánchez, S. Sepúlveda-Guzmán, L. E. Jasso- Ramos, and A. Castro-Beltrán"Synthesis of recycled poly (ethylene terephthalate)/polyacrylonitrile/styrene composite nanofibers by electrospinning and their mechanical properties evaluation," Journal of Polymers and the Environment, vol. 27, no. 3, pp. 659-669, 2019.

T. Oh, and C. Choi, "Comparison between SiOC Thin Film by plasma enhance chemical vapor deposition and SiO2 thin film by Fourier Transform Infrared Spectroscopy," Journal of the Korean Physical Society, vol. 56, no. 4, pp. 1150-1155, 2010.

L. Ma, P. Luo, Y. He, L. Zhang, Y. Fan, and Z. Jiang, "Ultra-stable silica nanoparticles as nano-plugging additive for shale exploitation in harsh environments," Nanomaterials, vol. 9, no. 12, p. 1683, 2019.

S. Wang, A. Ajji, S. Guo, and C. Xiong, "Preparation of microporous polypropylene/titanium dioxide composite membranes with enhanced electrolyte uptake capability via melt extruding and stretching," Polymers, vol. 9, no. 3, p. 110, 2017.

M. K. Ali, K. Ibrahim, O. S. Hamad, M. Eisa, M. Faraj, and F. Azhari, "Deposited indium tin oxide (ITO) thin films by dc-magnetron sputtering on polyethylene terephthalate substrate (PET)," Rom. J. Phys, vol. 56, no. 5-6, pp. 730-741, 2011.

Y. Li, Z. Zhao, D. Tang, M Kong, Q, Yang, Y. Huang, X. Liao, and Y. Niu, "Effect of nanoparticles on the morphology and properties of PET/PP in situ microfibrillar reinforced composites," Polymer Composites, vol. 38, no. 12, pp. 2718-2726, 2017.

Z. Zhang, C. Wang, and K. Mai, "Reinforcement of recycled PET for mechanical properties of isotactic polypropylene," Advanced Industrial and Engineering Polymer Research, vol. 2, no. 2, pp. 69-76, 2019.

S. Li, D. Xie, G. Qu, L. Yang, D. Min, and Y. Cheng, "Tailoring interfacial compatibility and electrical breakdown properties in polypropylene based composites by surface functionalized POSS," Applied Surface Science, vol. 478, pp. 451-458, 2019.

D. S. Morais, J. Cruz, R. Fangueiro, M. A. Lopes, and R. M. Guedes, "Characterization of polypropylene (PP) and poly (ethylene terephthalate) (PET) multifilament braided textile structures for Achilles tendon partial substitution," Mechanics of Materials, vol. 153, p. 103668, 2021.

T. Ohishi, K. Ichikawa, and S. Isono, "Heat-resistant properties of a SiO2-coated pet film prepared by irradiating a polysilazane-coated film with excimer light," Materials Sciences and Applications, vol. 11, no. 1, pp. 58-69, 2019.

M. Barczewski, K. Lewandowski, D. Rybarczyk, and A. Kloziński, "Rheological and single screw extrusion processability studies of isotactic polypropylene composites filled with basalt powder," Polymer Testing, vol. 91, p. 106768, 2020.

H. A. Faizi, R. Dimova, and P. M. Vlahovska, "A vesicle microrheometer for high-throughput viscosity measurements of lipid and polymer membranes," Biophysical Journal, vol. 121, no. 6, pp. 910-918, 2022.

F. Wang, Y. Wu, and Y. Huang, "High strength, thermostable and fast-drying hybrid transparent membranes with POSS nanoparticles aligned on aramid nanofibers," Composites Part A: Applied Science and Manufacturing, vol. 110, pp. 154-161, 2018.

J. Dang, S. Zhao, G. Chen, X. Cao, and J. Yang, "Effect of polyethylene powder and heating treatment on the micro-structure and hardened properties of foam concrete," Journal of Building Engineering, vol. 50, p. 104143, 2022.

D. Palomba, G. E. Vazquez, and M. F. Díaz, "Prediction of elongation at break for linear polymers," Chemometrics and Intelligent Laboratory Systems, vol. 139, pp. 121-131, 2014.

W. Brostow and D. Zhang, "Tensile elongation at break for polymers related to Vickers hardness," Materials Letters, vol. 276, p. 128179, 2020/10/01/ 2020.

L. H. Sperling, Introduction to physical polymer science. John Wiley & Sons, 2005.

ดาวน์โหลด

เผยแพร่แล้ว

วิธีการอ้างอิง

ฉบับ

บท

การอนุญาต

ลิขสิทธิ์ (c) 2023 วารสารโลหะ, วัสดุ และแร่

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.